Wide-Viewing Angle LCD Technology

A comprehensive guide to the most advanced display technologies powering modern visual experiences, from large monitors to the smallest small lcd screen applications.

Liquid Crystal Display (LCD) technology has evolved significantly since its inception, with viewing angle performance being one of the most critical advancements. Early LCDs suffered from severe color and contrast degradation when viewed off-axis, limiting their applicability in many scenarios.

Modern wide-viewing angle technologies have addressed these limitations, enabling consistent image quality across a broad range of viewing positions. This is particularly important for applications ranging from large format displays in public spaces to the small lcd screen found in smartwatches and portable devices, where users frequently view the screen from various angles.Optical Transceiver.

The fundamental challenge in achieving wide viewing angles lies in the anisotropic nature of liquid crystals—their optical properties change with the direction of light propagation and polarization. Different display modes have been developed to mitigate this issue, each employing unique approaches to control liquid crystal alignment and light transmission.

Today's leading technologies include Twisted Nematic (TN), Vertical Alignment (VA), In-Plane Switching (IPS), and Fringe Field Switching (FFS) modes. Each offers distinct trade-offs in viewing angle performance, response time, power consumption, and manufacturing cost, making certain technologies more suitable for specific applications than others.

LCD Technology Comparison

Viewing angle performance is typically measured by the extent to which contrast ratio and color accuracy are maintained as the viewer moves away from the direct front-facing position. A display is generally considered to have wide viewing angles if it maintains acceptable image quality at angles up to 80-85 degrees horizontally and vertically from the center.

The development of these technologies has been driven by the increasing demand for high-quality displays in diverse environments. From professional monitors requiring color accuracy at various positions to the small lcd screen in automotive applications where viewing angles can vary dramatically, wide-viewing angle technology has become a standard feature rather than a premium add-on.

Twisted Nematic (TN) – or lcd tn – is the oldest and most widely used LCD technology, dating back to the 1970s. Its enduring popularity stems from its relatively simple manufacturing process and lower production costs compared to other technologies.

In TN displays, liquid crystal molecules are naturally twisted between two glass substrates by approximately 90 degrees. When no voltage is applied, light passing through the first polarizer is rotated by these twisted molecules, allowing it to pass through the second polarizer (oriented perpendicular to the first). When voltage is applied, the molecules untwist, preventing light from passing through both polarizers.

The primary limitation of TN technology is its narrow viewing angle. Colors and contrast degrade significantly when viewed off-axis, particularly in the vertical direction. This is because the liquid crystal alignment is highly dependent on the viewing angle, causing changes in the polarization state of light passing through the display.

Despite this limitation, TN panels remain popular in applications where cost is a primary concern and viewing angles are less critical. This includes many computer monitors, especially those designed for gaming where fast response times are prioritized over wide viewing angles. The small lcd screen found in budget-friendly electronic devices often utilizes TN technology due to its cost-effectiveness.

Modern TN implementations have made incremental improvements in viewing angles through advanced electrode designs and optimized liquid crystal materials. However, these improvements have not matched the performance of other technologies specifically engineered for wide viewing angles. TN panels typically offer viewing angles of 140-150 degrees horizontally and 120-130 degrees vertically, which is significantly less than VA or IPS alternatives.

TN Mode Liquid Crystal Alignment

TN Mode Characteristics

- Lowest manufacturing cost

- Fastest response times

- Low power consumption

- Narrow viewing angles

- Limited color reproduction

- Ideal for small lcd screen applications

One of the key advantages of TN technology is its fast response time, which can be as low as 1ms, making it suitable for high-speed gaming and video applications. This responsiveness comes from the relatively low voltage required to change the alignment of the liquid crystals and their simple twisted structure.

In recent years, TN technology has faced increasing competition from IPS and VA alternatives, even in cost-sensitive markets. However, it remains a viable option for applications where viewing angle performance is secondary to cost and response time, including many small lcd screen devices such as calculators, digital watches, and basic consumer electronics.

Vertical Alignment (VA) technology, a prominent flat panel display advancement, represents a significant improvement in LCD viewing angle performance compared to TN panels. As the name suggests, VA displays feature liquid crystal molecules that align vertically (perpendicular to the substrate) when no voltage is applied.

When voltage is applied, the liquid crystals tilt towards the horizontal plane, allowing light to pass through the polarizers. The degree of tilt determines the amount of light transmitted, enabling grayscale reproduction. This vertical alignment approach inherently provides better viewing angle characteristics than TN technology.

VA panels are particularly known for their excellent contrast ratios, often exceeding 3000:1, which results in deep blacks and vibrant images. This makes them well-suited for home theater systems and other applications where image depth and richness are important. The technology has also been adapted for small lcd screen devices where both viewing angle and contrast are priorities.

Types of VA Technology

MVA (Multi-domain Vertical Alignment)

Developed by Fujitsu, MVA technology divides each pixel into multiple regions (domains) with liquid crystals tilted in different directions. This reduces off-angle color shift and improves viewing angles.

PVA (Patterned Vertical Alignment)

Samsung's PVA technology uses a patterned electrode structure to control liquid crystal alignment, achieving wider viewing angles and better color reproduction than conventional VA designs.

CPA (Continuous Pinwheel Alignment)

Sharp's CPA technology arranges liquid crystal alignment in a radial pattern, further minimizing viewing angle dependence and improving color consistency across the display.

VA panels typically offer viewing angles of 178 degrees both horizontally and vertically, representing a significant improvement over TN technology. This performance comes closer to matching IPS displays, though with some differences in color shift characteristics.

The response time of VA panels has improved significantly in recent years, with modern implementations achieving 5-8ms response times, making them suitable for most consumer applications including gaming and video playback. While not quite as fast as the fastest TN panels, the difference is often imperceptible to casual users.

In terms of manufacturing complexity and cost, VA technology falls between TN and IPS, offering a balance of performance and affordability. This positioning has made it popular in mid-range to high-end TVs, computer monitors, and increasingly in small lcd screen devices where the improved viewing angles and contrast justify the slightly higher production costs.

In-Plane Switching (IPS) technology revolutionized LCD viewing angles when it was introduced by Hitachi in 1996. Unlike TN and VA technologies that rely on vertical movement of liquid crystals, IPS employs a fundamentally different approach where liquid crystals rotate in the plane of the display.

IPS Technology

In IPS displays—a common type in lcd display monitors—liquid crystal molecules are aligned parallel to the substrate surfaces. When voltage is applied through electrodes located on the same substrate, the molecules rotate in the plane, changing their orientation relative to the polarizers. This in-plane rotation minimizes the dependence of optical properties on viewing angle.

The primary advantage of IPS technology is its exceptional viewing angle performance, typically 178 degrees horizontally and vertically, with minimal color shift and contrast degradation. This makes IPS displays ideal for professional applications such as graphic design, photo editing, and medical imaging where color accuracy across different viewing positions is critical.

IPS technology has been widely adopted in high-end smartphones, tablets, and monitors. Even in the small lcd screen of premium mobile devices, IPS technology ensures consistent color and brightness whether viewed head-on or from an angle.

FFS Technology

Fringe Field Switching (FFS) is a derivative of IPS technology developed to address some of its limitations. In FFS, the electrode structure is modified, with one electrode positioned above the other, creating a fringe electric field that extends across a larger area of the pixel.

This design allows for more efficient use of the pixel area, resulting in higher light transmission and lower power consumption compared to conventional IPS. The improved light efficiency is particularly beneficial for battery-powered devices and small lcd screen applications where power conservation is critical.

FFS technology maintains the excellent viewing angle characteristics of IPS while offering better sunlight readability due to its higher brightness capabilities. These attributes have made FFS a popular choice for mobile displays, e-readers, and automotive applications where both viewing angle performance and efficiency are important.

Advantages and Limitations

Key Advantages

- Superior viewing angles with minimal color shift

- Excellent color reproduction and accuracy

- Better touch screen performance due to stiffer substrate

- FFS variant offers improved power efficiency

- Consistent performance across various screen sizes, from large displays to small lcd screen devices

Limitations

- Higher manufacturing costs compared to TN and VA

- Slower response times than TN panels (though significantly improved in recent generations)

- Lower contrast ratios compared to VA technology

- Higher power consumption in standard IPS implementations

- More complex manufacturing process, particularly challenging for very small lcd screen production

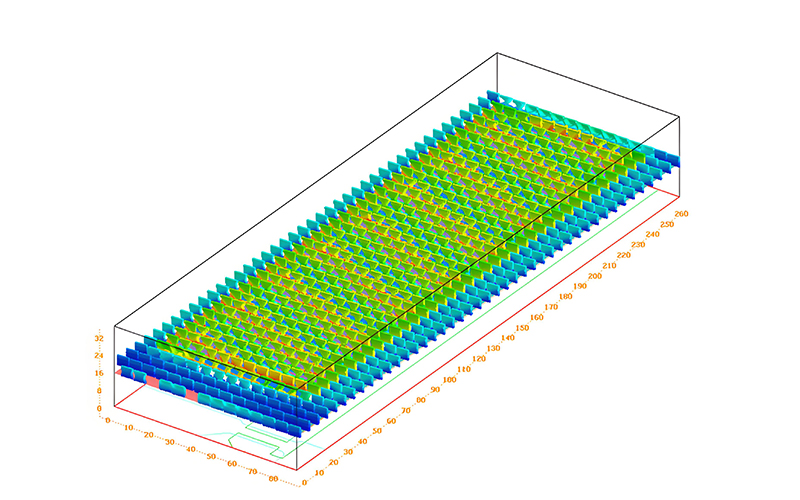

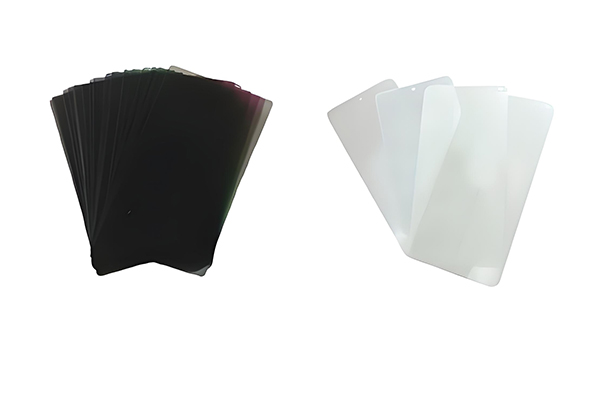

While advancements in liquid crystal alignment technologies (TN, VA, IPS, FFS) for lcd panels have been fundamental to improving viewing angles, polarizer and compensation film technologies play an equally critical role. These optical components work in conjunction with the liquid crystal layer to minimize color shift and contrast degradation when viewed off-axis.

Compensation Films Explained

Compensation films, also known as retardation films, are optical layers designed to correct the phase shift of light as it passes through the liquid crystal layer at different angles. These films introduce controlled birefringence to counteract the angle-dependent birefringence of the liquid crystals themselves.

The principle behind compensation films lies in their ability to adjust the polarization state of light, ensuring that it interacts correctly with the polarizers regardless of viewing angle. This is particularly important for maintaining consistent grayscale and color reproduction across the entire viewing range.

Different compensation film designs are optimized for specific liquid crystal modes. For example, TN panels typically use a single compensation film to address their specific viewing angle limitations, while IPS and VA technologies often employ more complex multi-layer compensation systems to achieve their superior performance. Even in the small lcd screen of portable devices, carefully engineered compensation films contribute significantly to viewing angle performance.

Multi-layer Polarizer and Compensation Film Structure

Types of Compensation Technologies

1. Uniaxial Compensation

This basic form of compensation uses a single layer with a uniform optical axis. It's commonly used in TN panels to improve their limited viewing angles by correcting for the asymmetric viewing angle characteristics.

Uniaxial films are cost-effective and relatively simple to manufacture, making them suitable for budget displays and small lcd screen applications where cost constraints are significant.

2. Biaxial Compensation

Biaxial films have two different optical axes, allowing them to correct for more complex polarization effects. This technology is often used in VA panels to enhance their already good viewing angle performance.

The additional complexity of biaxial compensation provides better color consistency across viewing angles, though at a higher manufacturing cost than uniaxial solutions.

3. Discotic Compensation

Discotic compensation films use disc-shaped molecules arranged in a layered structure, providing unique optical properties that are particularly effective for IPS technology.

This advanced technology helps IPS displays maintain their exceptional color accuracy across wide viewing angles, though it adds to the manufacturing complexity and cost.

4. Multi-Layer Systems

High-end displays often employ multiple layers of different compensation films, each addressing specific optical issues. This approach can provide optimal viewing angle performance across the entire panel.

While multi-layer systems offer the best results, they are the most expensive to implement and can increase the thickness of the display, making them less suitable for ultra-thin small lcd screen devices.

Advancements in Polarizer Technology

Polarizers themselves have also seen significant advancements. Modern polarizing films offer higher light transmission while maintaining polarization efficiency, contributing to brighter displays with lower power consumption.

Anti-reflective coatings on polarizers have improved sunlight readability, a critical factor for outdoor displays and mobile devices. These coatings minimize glare and reflection, ensuring the display remains visible even in bright conditions.

The integration of polarizer and compensation technologies has been particularly important for flexible displays and curved screens, where maintaining consistent viewing angles across the entire surface presents unique challenges. Even in the constrained space of a small lcd screen, these advanced optical films work together with the liquid crystal layer to deliver the best possible viewing experience.

Response time refers to the speed at which a pixel can change from one state to another, typically measured in milliseconds (ms). This parameter is crucial for display performance, particularly in applications involving fast-moving images such as gaming, video playback, and virtual reality.

Understanding Response Time Measurements

Response time is typically measured in two ways: gray-to-gray (GTG) and black-to-white-to-black (BWB). GTG measurements are more relevant for real-world performance as they represent the transition between different shades of gray, which occurs more frequently in typical content.

Slow response times can result in motion blur and ghosting artifacts, where previous pixel states remain visible during fast movement. This is particularly noticeable in action sequences in movies, sports broadcasts, and fast-paced games.

While larger displays often receive more attention for response time performance, it's equally important for small lcd screen devices. In fact, due to their higher pixel density relative to viewing distance, motion artifacts can be more perceptible on smaller screens if response times are not optimized.

Response Time Characteristics by Display Technology

TN Technology

Fastest response times among LCD technologies, typically 1-5ms GTG.

This speed advantage makes TN panels popular for competitive gaming, despite their viewing angle limitations.

Common applications: Gaming monitors, budget displays, basic small lcd screen devices

VA Technology

Moderate response times, typically 5-10ms GTG in modern implementations.

Recent advancements in VA technology have significantly improved response times, narrowing the gap with TN.

Common applications: TVs, mid-range monitors, some small lcd screen devices requiring better contrast

IPS/FFS Technology

Generally slower than TN, with typical response times of 4-15ms GTG.

Premium IPS panels use advanced driving techniques to achieve response times competitive with VA technology.

Common applications: Professional monitors, high-end TVs, premium small lcd screen devices

Technologies for Improving Response Time

Overdrive Technology

Overdrive (or impulse response) is a common technique where a higher voltage is applied to liquid crystals to speed up their movement. The voltage is carefully controlled to prevent overshoot artifacts.

This technique is widely used across all LCD technologies and is particularly effective for TN and VA panels. Overdrive can reduce response times by 30-50% in some cases, making it invaluable for both large displays and small lcd screen devices where fast motion is common.

Advanced Liquid Crystal Materials

New liquid crystal formulations with lower viscosity and faster switching properties have contributed significantly to response time improvements. These materials respond more quickly to electric fields, reducing transition times.

These advanced materials have been particularly important for improving the response times of IPS displays, helping them compete more effectively with TN technology while maintaining their viewing angle advantages.

Adaptive Driving Schemes

Modern LCD controllers use adaptive driving schemes that adjust pixel refresh rates and voltages based on content. This allows for optimized response times for fast-moving content while conserving power during static or slow-moving scenes.

For small lcd screen devices such as smartphones and gaming handhelds, these adaptive techniques are crucial for balancing performance and battery life. By only engaging high-performance driving when necessary, these displays can deliver responsive performance for gaming and video while extending battery life during other usage scenarios.

Contrast ratio is a fundamental display parameter that describes the difference between the brightest white and the darkest black that a display can produce. It is typically expressed as a ratio (e.g., 1000:1), where the first number represents the luminance of white and the second represents the luminance of black.

The Importance of Contrast

High contrast ratios are essential for producing images with depth, detail, and realism. A display with good contrast can render subtle shadow details in dark scenes while maintaining bright highlights, creating a more immersive viewing experience.

Contrast is particularly important for video content, photography, and gaming, where visual realism is valued. In professional applications such as photo editing and video post-production, accurate contrast reproduction is critical for making precise creative decisions.

While often associated with larger displays, contrast is equally important for small lcd screen devices. On smaller screens, the limited size makes high contrast even more critical for readability and image clarity, as it helps distinguish small details and text from background elements.

Contrast Ratio Comparison

TN Technology

Typically 500:1 to 1000:1

IPS Technology

Typically 1000:1 to 2000:1

VA Technology

Typically 3000:1 to 6000:1

VA with Local Dimming

Up to 1,000,000:1

Contrast Performance by Display Technology

TN Technology

TN panels generally offer the lowest contrast ratios among modern LCD technologies, typically ranging from 500:1 to 1000:1.

This limitation stems from their liquid crystal alignment structure, which allows more light leakage in dark states.

While sufficient for basic applications, TN's contrast limitations make it less suitable for media consumption, even in small lcd screen devices where image quality is important.

IPS/FFS Technology

IPS and FFS panels typically offer moderate contrast ratios in the range of 1000:1 to 2000:1.

While better than TN, IPS technology's in-plane switching mechanism still allows some light leakage in dark states, limiting contrast performance.

Premium IPS implementations use advanced pixel designs to reduce light leakage, making them suitable for high-end small lcd screen devices like professional tablets.

VA Technology

VA panels excel in contrast performance, typically offering ratios from 3000:1 to 6000:1, with some premium models exceeding 10,000:1.

The vertical alignment structure allows for better light blocking in dark states, resulting in deeper blacks and higher contrast.

This makes VA technology ideal for home theater systems and any application, including small lcd screen devices, where image depth and richness are priorities.

Technologies for Enhancing Contrast

Local Dimming

Local dimming is a backlight control technology that divides the backlight into separate zones that can be independently dimmed or brightened based on the content. This allows for deeper blacks in dark areas while maintaining brightness in bright areas.

While most commonly associated with larger displays like TVs, local dimming is increasingly being implemented in smaller screens, including high-end small lcd screen devices. Mini-LED backlighting has enabled more precise local dimming in compact form factors.

Advanced Pixel Designs

Modern pixel structures incorporate improved light-blocking elements and optimized liquid crystal alignment to minimize light leakage in dark states. This includes finer pixel gaps, improved black matrix materials, and more precise electrode patterns.

These advancements have been particularly important for improving the contrast of IPS displays, helping them compete more effectively with VA technology while maintaining their viewing angle advantages.

Dynamic Contrast Ratio

Dynamic contrast ratio is a feature where the display automatically adjusts the backlight brightness based on the overall brightness of the content. This can significantly increase measured contrast ratios by dimming the backlight for dark scenes.

While dynamic contrast can enhance the viewing experience for certain content, it's important to distinguish it from static contrast ratio, which measures the display's ability to reproduce bright and dark areas simultaneously. For small lcd screen devices, dynamic contrast can be particularly effective at improving readability in varying lighting conditions by optimizing overall brightness while maintaining the highest possible contrast for the current brightness level.Electronic shelf labels.

Summary of Wide-Viewing Angle LCD Technologies

The evolution of wide-viewing angle LCD technologies has transformed display performance, from the earliest TN panels to the advanced IPS and VA technologies available today. Each technology offers unique advantages, with viewing angle performance, response time, and contrast ratio being key differentiators.Related Hydraulic Spare Parts.

From large format displays to the smallest small lcd screen devices, these technologies continue to push the boundaries of what's possible, enabling more immersive, accurate, and versatile visual experiences across countless applications. Related Lithium Battery Manufacturing.