Liquid crystals represent a unique state of matter that exhibits properties of both conventional liquids and solid crystals. Discovered over a century ago, these materials have revolutionized display technology through the development of the liquid crystal display, which has become ubiquitous in modern life. This comprehensive overview explores the science behind liquid crystals, their classification, properties, synthesis, and diverse applications across numerous industries.

From the earliest observations to cutting-edge research, liquid crystals continue to offer new possibilities for technological innovation. The versatility of these materials, combined with ongoing advancements in their formulation and processing, ensures that the liquid crystal display and other liquid crystal-based technologies will remain at the forefront of modern engineering and design.

The story of liquid crystals begins in 1888 when Austrian botanist Friedrich Reinitzer observed that cholesteryl benzoate exhibited two distinct melting points. Between 145°C and 179°C, the substance formed a cloudy liquid with unusual optical properties before becoming a clear liquid at higher temperatures.

Reinitzer consulted German physicist Otto Lehmann, who recognized this as a new state of matter and coined the term "liquid crystals." Lehmann developed specialized microscopes to study these materials and published extensive research on their properties throughout the late 19th and early 20th centuries.

Despite this early research, practical applications remained limited for decades. It wasn't until the 1960s that significant progress occurred when RCA researchers George Heilmeier, Louis Zanoni, and Lucian Barton discovered electro-optical effects in liquid crystals, laying the groundwork for the first liquid crystal display technologies and the lcd invented.

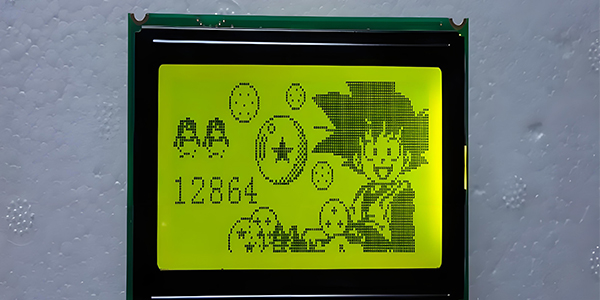

The 1970s saw the first commercial applications, including digital watches and calculators featuring simple liquid crystal display panels. These early displays used twisted nematic (TN) technology and required ambient light or backlighting to be visible.

Throughout the 1980s and 1990s, advancements accelerated with the development of super-twisted nematic (STN) displays, active-matrix addressing, and improved backlighting technologies. The 21st century has witnessed remarkable progress in liquid crystal display technology, including the development of in-plane switching (IPS), vertical alignment (VA) panels, and high-resolution displays for televisions, computer monitors, and mobile devices.

1888

Friedrich Reinitzer discovers liquid crystalline properties in cholesteryl benzoate

1889-1900

Otto Lehmann coins the term "liquid crystals" and conducts extensive research on their properties

1963

RCA researchers discover electro-optical effects in liquid crystals

1970s

First commercial liquid crystal display applications in watches and calculators

1980s-1990s

Development of STN displays and active-matrix technology for improved liquid crystal display performance

2000s-Present

Advancements in IPS, VA, and high-resolution liquid crystal display technologies for diverse applications

Early liquid crystal research equipment similar to that used by Otto Lehmann

Liquid crystals are classified based on their molecular arrangement, phase transitions, and symmetry properties. This classification system helps researchers and engineers understand and predict the behavior of different liquid crystal materials for various applications, including the development of advanced liquid crystal display technologies and what does lcd stand for.

Main Classification Categories

- Thermotropic liquid crystals – phase transitions depend on temperature

- Lyotropic liquid crystals – phase transitions depend on concentration in solvent

- Metallotropic liquid crystals – contain metal ions in their structure

Thermotropic liquid crystals are the most technologically important category, particularly for liquid crystal display applications. Within this category, three main structural types exist, each with distinct molecular arrangements and properties that determine their suitability for different display technologies.

Nematic

Molecules exhibit long-range directional order but no positional order, aligned parallel to each other.

Key Characteristics:

- Highly fluid

- Responsive to electric fields

- Used in most basic liquid crystal display technologies

Smectic

Molecules form layered structures with both directional and positional order within layers.

Key Characteristics:

- Less fluid than nematic

- Multiple subphases (A, B, C, etc.)

- Used in specialized liquid crystal display applications

Cholesteric

Chiral molecules form helical structures with layers that twist relative to each other.

Key Characteristics:

- Exhibits unique optical properties

- Reflects circularly polarized light

- Used in reflective liquid crystal display designs

Molecular Arrangement Comparison

Nematic Structure

Smectic Structure

Cholesteric Helical Structure

Liquid crystals exhibit a unique combination of physical properties that make them invaluable for numerous technological applications, especially in the liquid crystal display industry—such as arduino lcd display. These properties arise from their distinctive molecular structure, which combines aspects of both crystalline solids and amorphous liquids.

Anisotropic Properties

Liquid crystals exhibit direction-dependent properties, meaning their characteristics vary with measurement direction relative to molecular alignment.

- • Optical anisotropy (birefringence)

- • Dielectric anisotropy

- • Elastic anisotropy

- • Conductivity anisotropy

Optical Properties

The interaction of liquid crystals with light is fundamental to their use in liquid crystal display technology, enabling control over light transmission and polarization.

- • Birefringence (double refraction)

- • Polarization effects

- • Dichroism (selective absorption)

- • Light scattering properties

Electro-optical Effects

Applied electric fields can alter molecular alignment, changing optical properties – the fundamental principle behind liquid crystal display operation.

- • Twisted nematic effect

- • Guest-host effect

- • Dynamic scattering mode

- • In-plane switching

Thermotropic Behavior

Many liquid crystals exhibit temperature-dependent phase transitions, changing their structure and properties with heating or cooling.

- • Clear point (isotropic transition)

- • Melting point (crystal to LC transition)

- • Enthalpy of transitions

- • Temperature-dependent viscosity

Mechanical Properties

Liquid crystals possess unique flow characteristics and responses to mechanical stress that influence their processing and application.

- • Viscosity characteristics

- • Elastic constants

- • Response to shear forces

- • Surface alignment properties

Dielectric Properties

The interaction of liquid crystals with electric fields depends on their dielectric properties, critical for liquid crystal display functionality.

- • Dielectric anisotropy (Δε)

- • Frequency-dependent permittivity

- • Conductivity characteristics

- • Response time to electric fields

Optical Anisotropy in Liquid Crystals

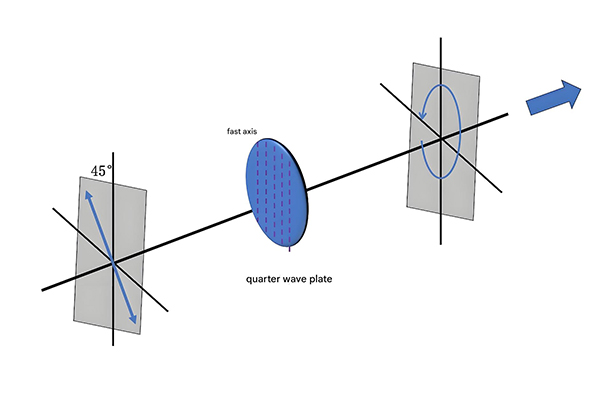

Optical anisotropy, or birefringence, is a key property enabling the functionality of liquid crystal display technology. This phenomenon occurs because the refractive index varies depending on the direction of light propagation relative to the molecular alignment.

When light enters a liquid crystal material, it splits into two components that travel at different velocities, resulting in a phase difference. This effect can be controlled by applying electric fields to change molecular orientation, forming the basis for image formation in liquid crystal display panels.

Dielectric Anisotropy Comparison

Dielectric anisotropy (Δε) is the difference between the dielectric constants parallel (ε∥) and perpendicular (ε⊥) to the molecular alignment. Positive Δε materials align with electric fields, while negative Δε materials align perpendicular to them. This property determines how liquid crystals respond to electric fields in a liquid crystal display.

Common Liquid Crystal Molecular Structures

Biphenyls

Two benzene rings connected directly

Phenylcyclohexanes

Benzene ring attached to cyclohexane

Cyanobiphenyls

Biphenyl with cyano end group

Esters

Benzene rings connected by ester group

Key Molecular Design Principles

- Rod-like shape for nematic phases

- Polar end groups to control dielectric properties

- 刚性中心结构维持分子有序性

- Flexible alkyl chains for optimal viscosity

Synthetic Methods for Liquid Crystal Molecules

The synthesis of liquid crystal molecules requires precise control over chemical structure to achieve the desired mesophase behavior and physical properties. These molecules are typically composed of a rigid core, flexible alkyl or alkoxy chains, and functional end groups – all carefully designed to optimize performance in applications like the liquid crystal display (the subject of what does l c d stand for).

Core Structure Synthesis

The rigid core, often composed of benzene rings, cyclohexane rings, or heterocyclic structures, forms the central portion of liquid crystal molecules. Aromatic substitution reactions, such as Suzuki coupling, Heck reaction, and Ullmann coupling, are commonly used to construct these core structures with high precision.

These reactions allow for the formation of carbon-carbon bonds between aromatic rings, creating the linear, rigid structures necessary for liquid crystalline behavior. The choice of core structure significantly influences the thermal stability and phase behavior of the resulting liquid crystal, critical factors for liquid crystal display performance.

Functional Group Incorporation

Functional groups are strategically incorporated to modify properties such as dielectric anisotropy, optical characteristics, and intermolecular interactions. Cyano groups (-CN), for example, increase dielectric anisotropy and are commonly used in nematic liquid crystals for liquid crystal display applications.

Other functional groups, including fluorine substituents, esters, and ethers, are used to fine-tune properties. Fluorinated liquid crystals have gained importance in advanced liquid crystal display technologies due to their improved voltage holding ratio, lower rotational viscosity, and better chemical stability.

Chain Attachment

Flexible alkyl or alkoxy chains (typically 5-12 carbon atoms) are attached to the rigid core to control melting points and viscosity. Longer chains generally lower melting points but increase viscosity, requiring careful optimization for specific applications. These chains are often introduced through etherification, esterification, or alkylation reactions, with the length and branching precisely controlled to achieve the desired balance of properties for liquid crystal display operation.

Structure-Property Relationships

Understanding how molecular structure influences properties is essential for designing liquid crystals with specific characteristics for liquid crystal display and other applications.

| Molecular Feature | Effect on Properties | Relevance to liquid crystal display |

|---|---|---|

| Core Length | Longer cores increase nematic phase stability and birefringence | Affects display contrast and operating temperature range |

| Alkyl Chain Length | Longer chains reduce melting point but increase viscosity | Balances operating temperature and response time |

| Polar End Groups | Increase dielectric anisotropy and intermolecular forces | Reduces operating voltage in liquid crystal display panels |

| Fluorine Substituents | Reduce viscosity, improve chemical stability | Enables faster response times and longer display life |

| Branched Chains | Reduce melting point, disrupt molecular packing | Improves low-temperature performance |

Purification and Characterization

After synthesis, liquid crystal compounds require rigorous purification to remove impurities that can degrade performance in applications like liquid crystal display technology. Common purification techniques include:

Purification Methods

- • Column chromatography

- • Recrystallization

- • Vacuum distillation

- • Zone refining

- • Supercritical fluid extraction

Characterization Techniques

- • Polarizing optical microscopy

- • Differential scanning calorimetry (DSC)

- • X-ray diffraction

- • Nuclear magnetic resonance (NMR)

- • Dielectric spectroscopy

These purification steps are critical because even trace impurities can significantly impact the electro-optical properties of liquid crystals, leading to reduced performance and reliability in liquid crystal display devices. Characterization ensures that the synthesized materials meet the strict specifications required for commercial applications.

Commercial liquid crystal materials used in liquid crystal display technology are almost exclusively mixtures of multiple liquid crystal compounds. These blends are carefully formulated to achieve the optimal combination of properties required for specific display applications like 16x 2 lcd display pins, as no single compound can meet all performance requirements.

Key Parameters of Liquid Crystal Mixtures

Phase Transition Temperatures

Clear point (Tc) and melting point (Tm) define the operating temperature range. For liquid crystal display applications, mixtures must remain in the nematic phase across typical operating temperatures (usually -20°C to 70°C or wider).

Viscosity

Rotational viscosity (γ₁) directly impacts liquid crystal display response time. Lower viscosity enables faster pixel switching, crucial for video applications and reducing motion blur.

Dielectric Anisotropy (Δε)

The difference between parallel and perpendicular dielectric constants determines the voltage required to reorient molecules. Higher Δε reduces operating voltage in liquid crystal display panels.

Birefringence (Δn)

The difference between extraordinary and ordinary refractive indices determines the optical path length. Proper matching with cell gap is critical for liquid crystal display contrast and brightness.

Elastic Constants (K₁₁, K₂₂, K₃₃)

These constants describe the material's resistance to deformation. They influence response time, viewing angle, and threshold voltage in liquid crystal display devices.

Impact of Parameters on Display Performance

The relationship between liquid crystal material properties and liquid crystal display performance metrics is complex and interdependent.

Response Time

Primarily determined by rotational viscosity (γ₁) and elastic constants. Lower viscosity and higher elastic constants reduce response time, critical for fast-moving content in liquid crystal display panels used for gaming and video.

Operating Voltage

Directly related to dielectric anisotropy (Δε) and elastic constants. Higher Δε allows lower operating voltages, reducing power consumption in liquid crystal display devices – a key consideration for mobile applications.

Contrast Ratio

Influenced by birefringence (Δn), cell gap, and alignment quality. Properly optimized birefringence ensures maximum light modulation, enhancing contrast in liquid crystal display panels under various lighting conditions.

Viewing Angles

Determined by elastic constants, dielectric anisotropy, and molecular orientation. Mixtures with balanced elastic constants combined with advanced liquid crystal display modes (like IPS) provide wider viewing angles.

Temperature Stability

Dependent on phase transition temperatures and temperature coefficients of viscosity and birefringence. Critical for liquid crystal display operation in extreme environments, from automotive to aerospace applications.

Liquid Crystal Mixture Optimization for Specific Applications

| Application | Key Requirements | Optimized Parameters | Typical Mixture Characteristics |

|---|---|---|---|

| TV and Monitors | Fast response, wide viewing angles, high contrast | Low γ₁, balanced K constants, moderate Δn | Fluorinated nematics with Δε > 5, Tc > 70°C |

| Mobile Devices | Low power, high brightness, wide temperature range | High Δε, low viscosity, wide T range | High Δε (>10) mixtures with Tc > 90°C, Tm < -30°C |

| Automotive Displays | Extreme temperature stability, high reliability | Very wide T range, low temp coefficient | Specialized mixtures with Tc > 100°C, Tm < -40°C |

| Gaming Displays | Ultra-fast response, high refresh rates | Very low γ₁, optimized elastic constants | Low viscosity mixtures with response < 1ms |

| VR Displays | Ultra-fast response, high resolution | Extremely low γ₁, high Δn | Specialized low-viscosity formulations |

Formulation Challenges

Creating optimized liquid crystal mixtures is a complex balancing act, as improving one property often negatively impacts another. For example, increasing dielectric anisotropy may also increase viscosity. Manufacturers employ sophisticated modeling and experimental techniques to develop mixtures that meet the specific requirements of each liquid crystal display application while maintaining overall performance balance.

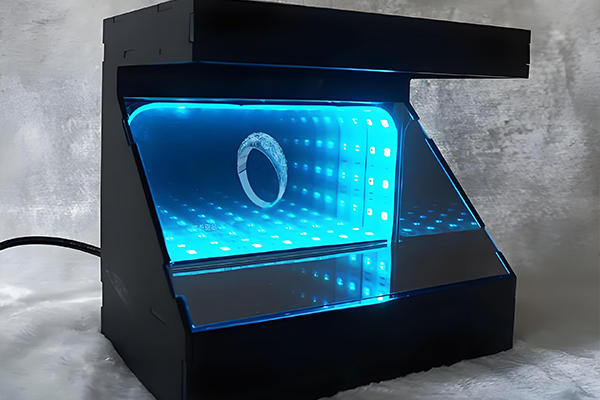

Liquid crystals have found widespread applications across numerous industries, with lcd displays being the most well-known. Their unique combination of optical, electrical, and mechanical properties makes them versatile materials for diverse technological uses, from consumer electronics to advanced scientific instruments.

Display Technologies

The most prominent application of liquid crystals is in the liquid crystal display, which has revolutionized visual technology across numerous devices.

- • Televisions and monitors

- • Smartphone and tablet screens

- • Laptop displays

- • Digital signage

- • Wearable devices

- • Automotive displays

Optical Devices

Beyond displays, liquid crystals enable various optical components with adjustable properties.

- • Variable optical attenuators

- • Tunable lenses and filters

- • Optical switches for telecommunications

- • Adaptive optics systems

- • Laser beam steering devices

- • Privacy glass and smart windows

Sensing and Measurement

Liquid crystals' sensitivity to various stimuli makes them valuable for sensing applications.

- • Temperature sensors

- • Pressure and strain sensors

- • Chemical and biological sensors

- • Radiation detectors

- • Voltage and electric field sensors

- • Toxic gas detectors

Photonics

In photonics, liquid crystals enable control over light properties for advanced applications.

- • Liquid crystal lasers

- • Polarization controllers

- • Holographic devices

- • Spatial light modulators

- • Integrated photonic circuits

- • Quantum photonics components

- • Quantum photonics components

Biomedical Applications

Liquid crystals offer unique capabilities in medical diagnostics and therapies.

- • Biosensors for disease detection

- • Lab-on-a-chip devices

- • Controlled drug delivery systems

- • Tissue engineering scaffolds

- • Medical imaging contrast agents

- • Diagnostic test kits

Energy Applications

Emerging uses of liquid crystals in energy generation and management.

- • Smart windows for energy efficiency

- • Solar cell components

- • Thermal energy storage

- • Energy-efficient lighting

- • Battery components

- • Fuel cell membranes

Advanced liquid crystal display Technologies

The liquid crystal display technology continues to evolve, with ongoing innovations pushing performance boundaries. These advancements address limitations in viewing angles, response time, contrast ratio, and power consumption.

In-Plane Switching (IPS)

Molecules rotate in the plane of the display, offering superior viewing angles and color reproduction compared to traditional TN displays. IPS technology has become standard for high-end liquid crystal display monitors and smartphones.

Vertical Alignment (VA)

Molecules align vertically when no voltage is applied, achieving deep blacks and high contrast ratios. VA panels offer a balance between IPS and TN technologies, commonly used in liquid crystal display televisions.

Quantum Dot liquid crystal display

Incorporates quantum dots to enhance color gamut and brightness. This hybrid technology combines the benefits of quantum dot light sources with liquid crystal display pixel control, delivering performance approaching OLED displays.

Mini-LED Backlit liquid crystal display

Uses thousands of tiny LEDs for backlighting with local dimming, significantly improving contrast ratio and black levels. This technology brings liquid crystal display performance closer to OLED while maintaining advantages in brightness and longevity.

High Refresh Rate Displays

120Hz, 144Hz, and even 240Hz refresh rates, enabled by low-viscosity liquid crystal mixtures, reduce motion blur and improve gaming and fast-action content viewing on liquid crystal display panels.

MicroLED-Integrated liquid crystal display

Emerging technology combining microLED backlighting with liquid crystal display pixel control for unprecedented brightness, contrast, and color performance while maintaining scalability.Lithium-Ion Battery.

Comparison of modern liquid crystal display technologies showing improvements in contrast and viewing angles

Future Directions and Emerging Applications

Flexible Displays

Development of flexible and foldable liquid crystal display technologies using flexible substrates and specialized liquid crystal materials, enabling new form factors for mobile devices and wearables.

Energy Harvesting

Liquid crystal-based devices that convert ambient light or heat into electrical energy, potentially powering small electronics and contributing to the Internet of Things ecosystem.

AR/VR Displays

Advanced liquid crystal display solutions for augmented and virtual reality with ultra-high resolution, fast response times, and low latency to create immersive experiences.Electronic shelf labels.

As research continues, liquid crystals will undoubtedly find new applications across emerging technologies. The liquid crystal display remains at the forefront of these developments, constantly evolving to meet the increasing demands of consumers and industries for higher performance, greater efficiency, and innovative form factors.Related Hydraulic Spare Parts